ROBOTIC SPRAY PAINTING

ROBOTIC SPRAY PAINTING

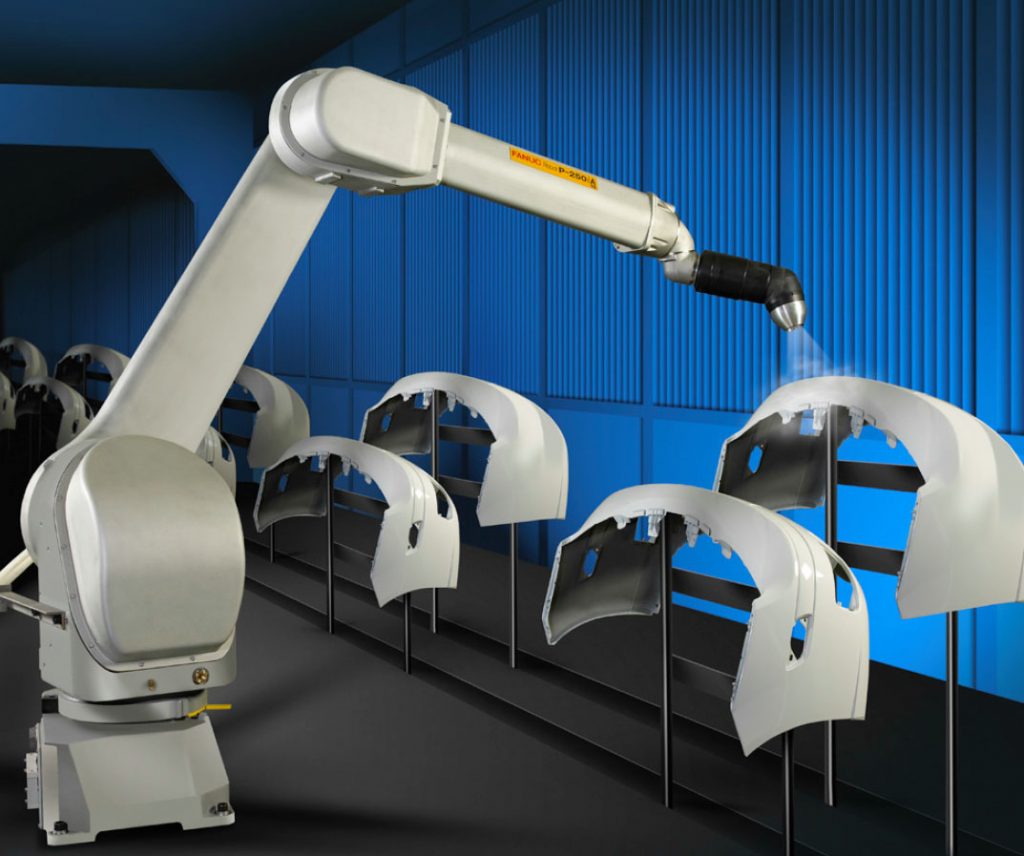

Mostly used by vehicle manufacturers to do detailing works on their vehicles in a systematic way.

Our spray painting machine & painting robot is widely applied in a big range industries for surface treatment such as car parts, houseware parts, plastic & hardware parts etc.

Robotic spray painting arm is a painting process in which spray painting is done by robots arm to reduce the human load. Robotic spray painting arm has been used for many year in automotive spray painting applications. The early version of robotic spray painting is hydraulic which are still in used today by many industries although they are of inferior quality and safety when compared with the latest electronics offerings.

The choosing of modern robotic spray painting arm differs much more in size and payload to reach many painting item of all sizes. spray painting robot have five to six axis motion originally, three for the base motions, while they have also up to three for applicator orientation.

Advantages for robot painting and spray-coating applications

Spray-coating programs for robots can be generated automatically from the CAD model and subsequently modified with minimal effort to adjust for:

- Change of spray shape

- Nozzle diameter

- Nozzle to part distance

- Depth of passes

- Number of coats

- Entry/exit can be managed to extend automatically beyond the CAD model

- Automatically manage and change the distance between steps without re-programming the part

- Even step distances ensure spray consistency

- Tool orientations can be managed automatically to optimize the program for minimal wrist rotation and maximize robot reach