Introduction

Cubic printing technology brings colors to products. Diverse expressions are shown, as if breathing life into in animated materials. Cubic printing creates fresh, new designs and is the unique multi-colored 3D printing technology without regard to shapes or substrate material. The cubic printing technology can decorate plastic, metals and ceramic, audio-video products to automotive interiors, expressing high-quality woods and sharply defined lined-patterns. Our technology started with automotive, cellular phones, household appliances and has expanded into interior decoration, proving its flexibility and growth. By granting the cubic printing license to various companies throughout the world, the cubic printing network was created and an even more sophisticated, stable process has continued to this day.

We at Arion, with even greater activity, continue to implement our technical and design developments, participating in new markets, creating total design and new product planning, and expanding the ‘human’ possibilities of Cubic printing.

The Company

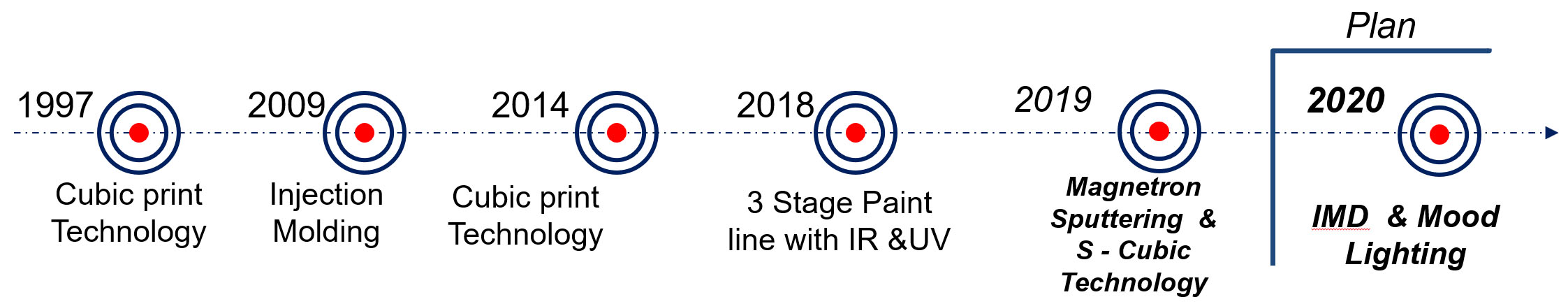

Arion Technologies Ltd commenced in business since 1997. It is a Joint venture with M/s. Taica Corporation, Japan. Pioneers in 3-D decoration technology in India, Arion has designed, developed & processed products with a variety of different finishes, textures and colors targeting manufacturers in different fields. Some of our customers include Toyota, General Motors, Fiat, Tata Motors, Maruti Suzuki, and Mahindra & Mahindra. Company has 4 units with good infrastructure.

Our Cubic printing Technology reduces costs, improve look and feel of real material on less expensive substrates. Our technology started with automotive, cellular phones, household appliances and has expanded into interior decoration, proving its flexibility and growth. By granting the Cubic Printing license to various companies throughout the world, the Cubic Printing Network was created and an even more sophisticated, stable process has continued to this day.

Our Plastic Injection Moulding Facility specializing in Automotive trims and home appliances to provide its customers a one stop solutions for OE fitment and post production process like painting, cubic printing and PVD chrome.

Our PVD chrome fully eco-friendly and no toxic chemical disposal. No use of Cr6 ,Ni, Pb, Hg and any other toxic components. It can be applied on any thermoplastic, thermoset metal and rubber material even TPU /TPO (flexible material). It can be given any kind of color with high gloss / low gloss.

Achievements & Awards

Quality Management System