MAGNETRON SPUTTERING

MAGNETRON SPUTTERING COATING

Allows the deposition of metals, alloys, ceramic, and polymer thin films onto a wide range of substrate materials.

100% environmentally green process unlike tradition chrome plating.It can applied on any thermoplastic, thermoset metal and rubber material even TPU /TPO

What is Magnetron Sputtering Coating

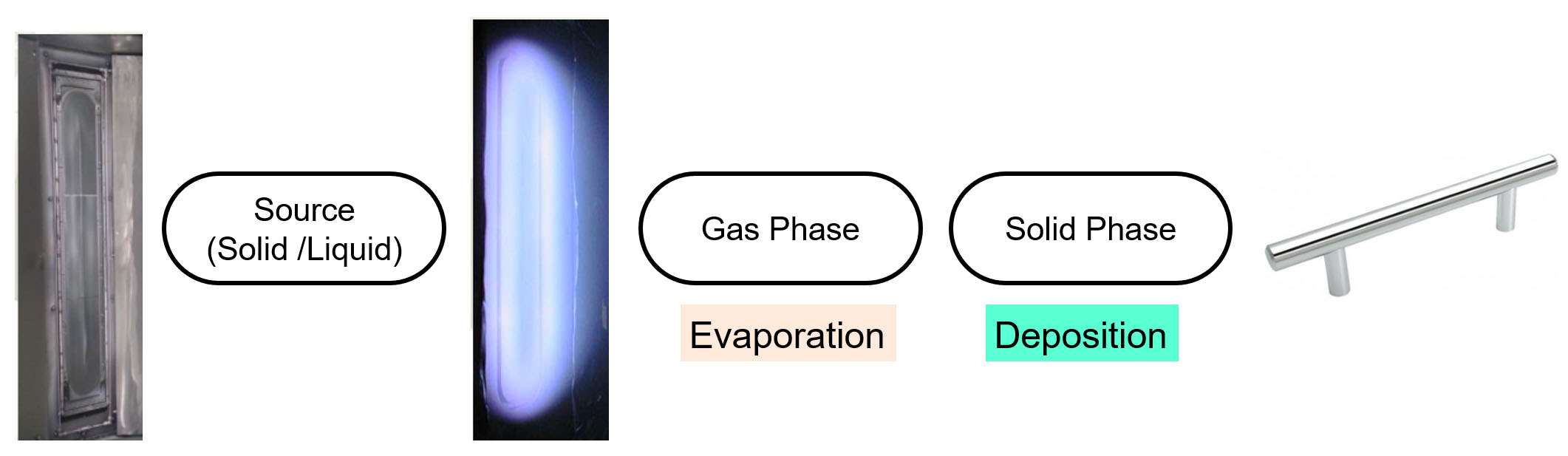

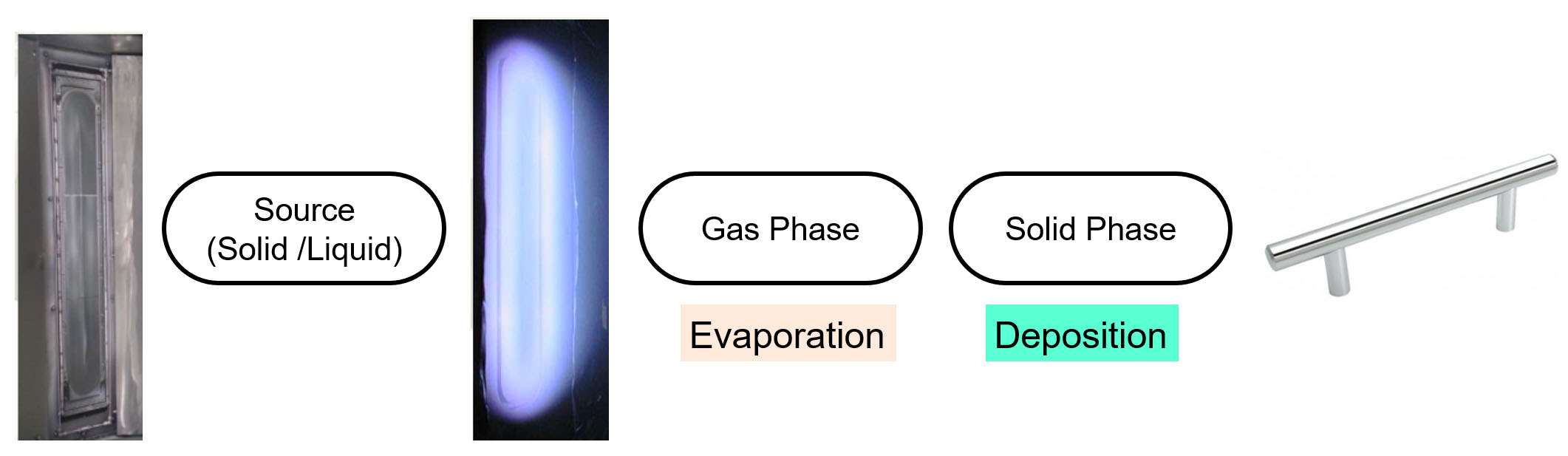

Physical vapor deposition (PVD) describes a variety of vacuum deposition methods which can be used to produce thin films and coatings. PVD is characterized by a process in which the material goes from a condensed phase to a vapor phase and then back to a thin film condensed phase. The most common PVD processes are sputtering and evaporation.

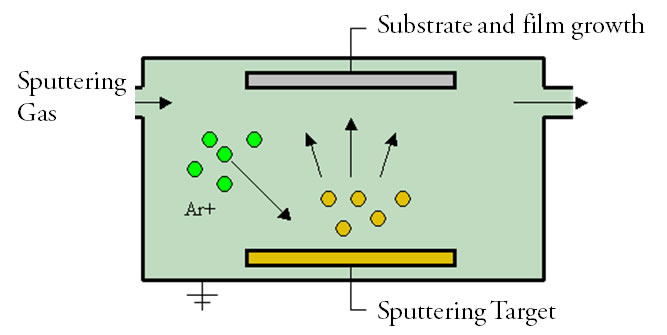

Thus, PVD by Sputtering is a term used to refer to a physical vapor deposition (PVD) technique wherein atoms or molecules are ejected from a target material by high-energy particle bombardment so that the ejected atoms or molecules can condense on a substrate as a thin film.

Magnetron Sputtering Coating Process

- Use Large area targets which gives uniform thickness over the wafer

- Control the thickness by deposition time and other parameters

- Even materials with very high melting points are easily sputtered

- Sputtered film typically have a better adhesion on the substrate

- Sputtering can be performed top-down

- Ions are generated and directed at a target

- The ions sputter targets atoms

- The ejected atoms are transported to the substrate

- Atoms condense and form a thin film

Advantages of Magnetron Sputtering Coating

- Environment- Friendly process and coatings

- No chemical disposals

- No use of Cr6 ,Ni, Pb, Hg and any other toxic components

- It can applied on any thermoplastic, thermoset metal and rubber material even TPU /TPO (flexible material)

- It can be given any kind of color with high gloss / low gloss.

Applications